HARD ANODIZE OF ALUMINUM

Hardcoat anodize is specified for aluminum components subject to extreme wear applications where superior abrasion resistance is needed, or corrosive environments where a thicker, harder, more durable coating is necessary.

Hardcoat Anodize can also be valuable where enhanced electrical insulation is required. Since Hardcoat can be built up to several thousandths in, it also makes this type of anodize a candidate for salvaging worn or mis-machined components.

Hard Anodize Features

- Improved wear resistance

- Non-conductive

- Can repair worn surfaces on aluminum

- Improve parts surface for slide applications

- Can be black dyed; other colors less decorative

- Finish is harder than tool steel

- Can be ground or lapped

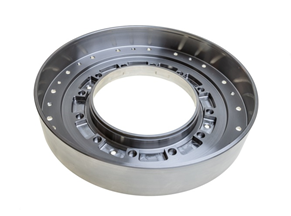

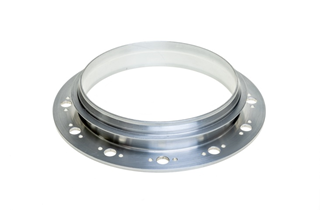

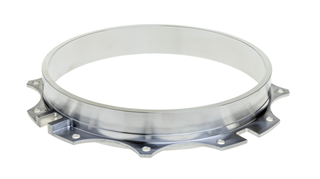

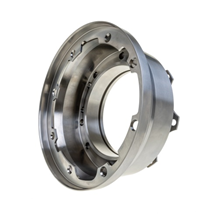

See examples of our Hard Coat Anodized Aluminum machining work

Industry: Aerospace Machining

Materials: Investment Casting

Industry: Automotive

Materials: Sand Casting

Industry: Military

Materials: Investment Casting

Industry: Aerospace Machining

Materials: 17-4PH Investment Casting

Industry: Military

Materials: 4140 Investment Casting

Industry: Military

Materials: 17-4PH Investment Casting

Industry: Military

Materials: 4140 Investment Casting

Industry: Military

Materials: Investment Casting

Industry:

Materials:

Industry: Military

Materials: Investment Casting

Industry: Military

Materials: Forging

Industry: Military

Materials: 4340 Forging

Industry: Military

Materials: Forging

Industry: Firearms

Materials: 410 Stainless

Industry: Firearms

Materials: 416 Stainless

Industry: Firearms

Materials: 410 Stainless

Industry: Aerospace Machining

Materials: Aluminum

Industry: Aerospace Machining

Materials: Stainless Steel

Industry: Aerospace Machining

Materials: Stainless Steel

Industry: Aerospace Machining

Materials: Aluminum

Industry: High Tech

Materials: Aluminum

Industry: High Tech

Materials: Aluminum

Industry: High Tech

Materials: Molybdenum

Industry: High Tech

Materials: Molybdenum

Industry: Military

Materials: 17-4PH

Industry: High Tech

Materials: Hastelloy

Industry: Aerospace Machining

Materials: Hastelloy

Industry: Aerospace Machining

Materials: Stainless Steel

Industry: High Tech

Materials: Monel

Industry: Aerospace Machining

Materials: 15-5PH

Industry: Aerospace Machining

Materials: 15-5PH

Industry: Aerospace Machining

Materials: 17-4PH

Industry: Aerospace Machining

Materials: Aluminum

Industry: High Tech

Materials: Inconel

Industry: Aerospace Machining

Materials: Titanium

Industry: Aerospace Machining

Materials: Stainless Steel

Industry: Aerospace Machining

Materials: Stainless Steel

Industry: Aerospace Machining

Materials: Titanium

Industry: Aerospace Machining

Materials: Titanium

Industry: High Tech

Materials: Aluminum

Industry: Military

Materials: 4140 Investment Casting

Industry: Military

Materials: Titanium

Industry: Military

Materials: Anodized Aluminum

Industry: Military

Materials: Titanium

Industry: High Tech

Materials: Nitronic 60

Industry: Aerospace Machining

Materials: Other Alloys

Industry: Firearms

Materials: 410 Stainless

Industry: Military

Materials: Inconel

Industry: Aerospace Machining

Materials: Aluminum

Industry: Aerospace Machining

Materials: Aluminum

Industry: Aerospace Machining

Materials: Nitronic 60

Industry: Aerospace Machining

Materials: Monel

Industry: Military

Materials: Titanium

Industry: Aerospace Machining

Materials: 17-4PH

Industry: Military

Materials: Monel

Industry: Aerospace Machining

Materials: Aluminum

Industry: Aerospace Machining

Materials: A286

Industry: High Tech

Materials: Hastelloy

Industry: Aerospace Machining

Materials: 410 Stainless

Industry: Aerospace Machining

Materials: Titanuim

Industry: Military

Materials: Titanium

Industry: Military

Materials: Titanium

Industry: Firearms

Materials: Titanium

Industry: Aerospace Machining

Materials: Aluminum

Industry: Military

Materials: Inconel